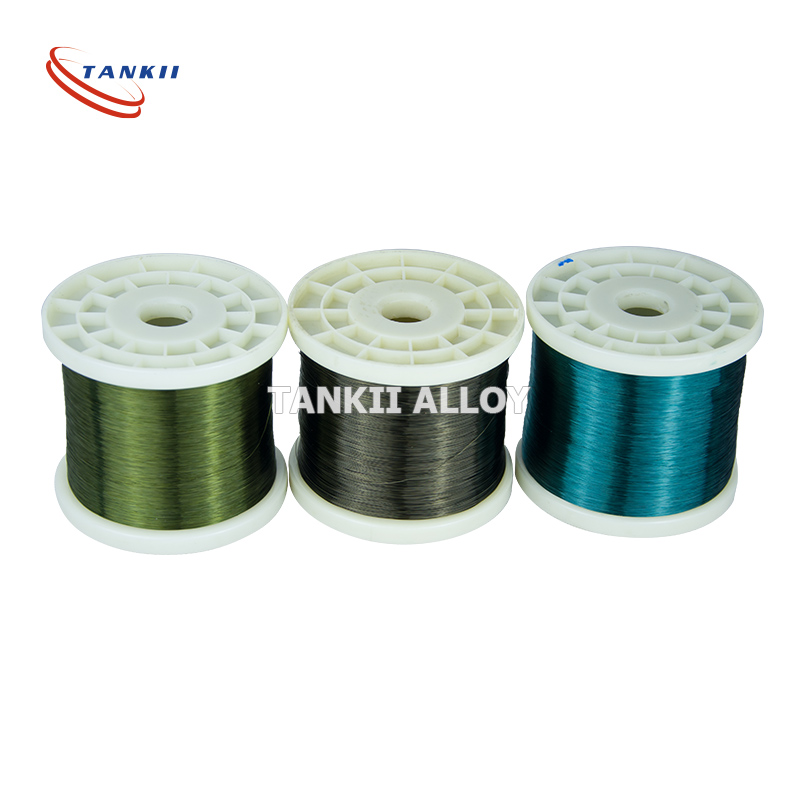

Tariby varahina kilasy C / 200*C ANSI TYPE MW35C na IEC 317-13. Tariby fanidiana enamel voarakotra roa sosona vita amin'ny polyester-imide sy polyamide-imide

tariby varahina kilasy mafana C/ 200*C ANSI KARAZANA MW35C na IEC 317-13. Polyester-imide sypoliamida-imidaTariby mihodinkodina misy enamely roa sosona

Mombamomba ny vokatra

Ireo tariby fanoherana vita amin'ny enamel ireo dia efa nampiasaina betsaka tamin'ny resistor mahazatra, fiara

ampahany, resistors amin'ny windings, sns. amin'ny fampiasana nyinsulationfanodinana izay mety indrindra amin'ireo fampiharana ireo, amin'ny fampiasana tanteraka ireo endri-javatra miavaka amin'ny coating enamel.

Ankoatra izany, dia hanao coating enamel izahayinsulationtariby metaly sarobidy toy ny tariby volafotsy sy platina rehefa manafatra. Azafady ampiasao ity "production-on-order" ity.

Karazana tariby Nichrome

NiCr80/20,NiCr70/30,NiCr60/15,NiCr90/10,NiCr35/20,NiCr30/20

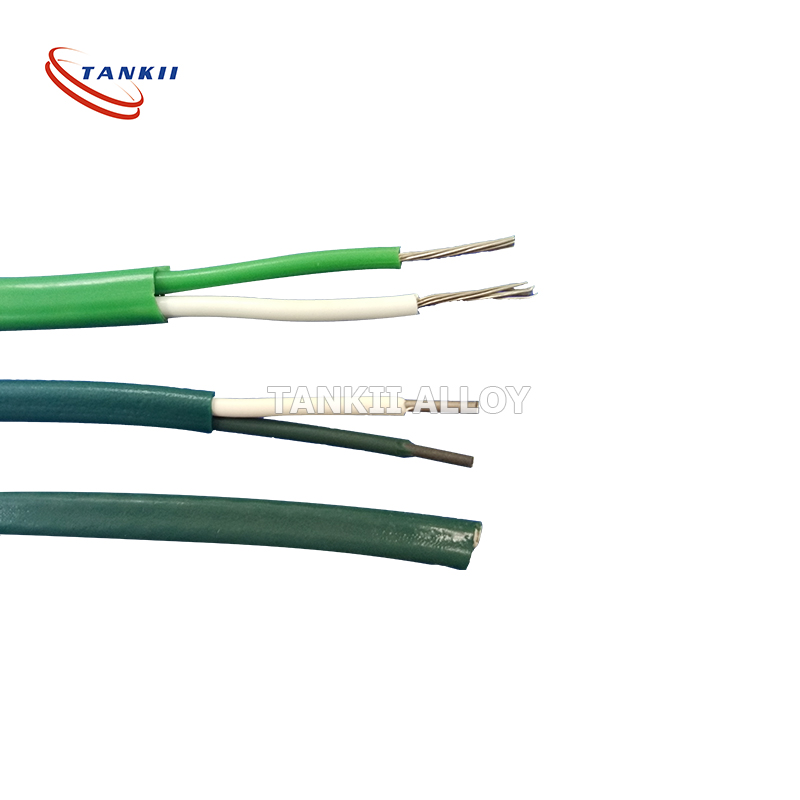

Karazana Insulation

| Anarana misy enamel insulation | Haavo mafanaºC (fotoana fiasana 2000h) | Anaran'ny kaody | Kaody GB | KARAZANA ANSI |

| Tariby polyurethane enamelled | 130 | UEW | QA | MW75C |

| Tariby polyester enamelled | 155 | dabilio | QZ | MW5C |

| Tariby polyester-imide enamelled | 180 | EIW | QZY | MW30C |

| Tariby misy enamel roa sosona vita amin'ny polyester-imide sy polyamide-imide | 200 | EIWH (DFWF) | QZY/XY | MW35C |

| Tariby polyamide-imide enamelled | 220 | AIW | QXY | MW81C |

Karazana tariby firaka miboridana

Ny firaka azontsika atao amin'ny enamel dia tariby firaka varahina-nikela, tariby Constantan, tariby Manganin. Tariby Kama, tariby firaka NiCr, tariby firaka FeCrAl sns.

| fototra NY FANANANA karazana | Cuni1 | CuNI2 | CuNI6 | CuNi8 | CuNI10 | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNI44 | ||

| fototra simika fifehezan | Ni | 1 | 2 | 6 | 8 | 10 | 14.2 | 19 | 23 | 30 | 34 | 44 | |

| MN | / | / | / | / | / | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | ||

| CU | HAFA | HAFA | HAFA | HAFA | HAFA | HAFA | HAFA | HAFA | HAFA | HAFA | HAFA | ||

| fara-tampony MIASÀ hafanana | / | 200 | 220 | 250 | 250 | 300 | 300 | 300 | 350 | 350 | 400 | ||

| hakitroky g/sm3 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | ||

| fanoherana amin'ny 20°C | 0.03 ± 10% | 0.05± 10% | 0.10± 10% | 0.12± 10% | 0.15± 10% | 0.20± 5% | 0.25± 5% | 0.30± 5% | 0.35± 5% | 0.40± 5% | 0.49± 5% | ||

| hafanana koefisienan'ny fanoherana | <100 | <120 | <60 | <57 | <50 | <38 | <25 | <16 | <10 | -0 | <-6 | ||

| tensile tanjaka mpa | >210 | >220 | >250 | >270 | >290 | >310 | >340 | >350 | >400 | >400 | >420 | ||

| fanalavana | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | ||

| mitsonika teboka °c | 1085 | 1090 | 1095 | 1097 | 1100 | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | ||

| koefisienan'ny fitarihana herinaratra | 145 | 130 | 92 | 75 | 59 | 48 | 38 | 33 | 27 | 25 | 23 |

tariby fanafanana vita amin'ny firaka nicr8020

1. Momba ny tariby Nichrome

Ny firaka nikrôma dia ahitana nikela madio, firaka NiCr, firaka Fe-Cr-Al ary firaka nikela varahina.

Firaka nikela chrome: Ni80Cr20, Ni70Cr30, Ni60Cr15, Ni35Cr20, Ni30Cr20, Cr25Ni20, nikela madio Ni200 sy Ni201

2. Tombony lehibe sy fampiharana

1. Nikela-krôma, firaka nikela-krôma manana fanoherana avo sy marin-toerana, fanoherana ny harafesina, fanoherana ny oksidasiona amin'ny ety ambonin'ny tany, tsara kokoa amin'ny mari-pana avo sy ny herin'ny horohoron-tany, mora miolaka, mora miasa ary mora miolaka.

2. Ny vokatray dia mihatra betsaka amin'ny indostrian'ny simika, ny mekanisma metalurgia, ny indostrian'ny fitaratra, ny indostrian'ny seramika, ny sehatry ny fitaovana an-trano sy ny sisa.

3. Ny firafitry ny simika:

| Marika | Firafitra simika | Si | Cr | Ni | Al | Fe | |||

| C | P | S | Mn | ||||||

| Tsy mihoatra ny | |||||||||

| Cr20Ni80 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 20.0-23.0 | AZA | ≤0.50 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 15.0-18.0 | 55.0-61.0 | ≤0.50 | AZA |

| Cr20Ni35 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-3.00 | 18.0-21.0 | 34.0-37.0 | - | AZA |

| Cr20Ni30 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-2.00 | 18.0-21.0 | 30.0-34.0 | - | AZA |

Rehefa "M" ny sata ny vokatra dia tokony harahina ny fenitra GB/T1234-1995

Resistivity:

| Marika | Cr20Ni80 | Cr20Ni60 | Cr20Ni35 | Cr20Ni30 | ||

| Savaivony mm | <0.50 | 0.50-3.0 | <0.50 | ≥0.50 | <0.50 | ≥0.50 |

| fanoherana (20°C)uΩ·m | 1.09±0.05 | 1.13±0.05 | 1.12±0.05 | 1.15±0.05 | 1.04±0.05 | 1.06±0.05 |

Sokajy vokatra

-

Phone

-

Mailaka

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Ambony